Introduction

Dans le monde de l'automobile moderne, les roulements de moyeu de roue jouent un rôle essentiel en matière de sécurité, de performance et de confort. Parmi les différents types de roulements de moyeu, le Palier de moyeu de la génération 1 (Palier de moyeu G1) est la plus utilisée et sert de base à des conceptions plus avancées. Cet article présente une vue d'ensemble du roulement de moyeu de génération 1, y compris sa structure, ses fonctions, ses avantages, ses applications, son entretien et sa comparaison avec les générations suivantes. Si vous recherchez des informations précises et adaptées au référencement sur les roulements de moyeu, ce guide vous aidera à comprendre tout ce que vous devez savoir.

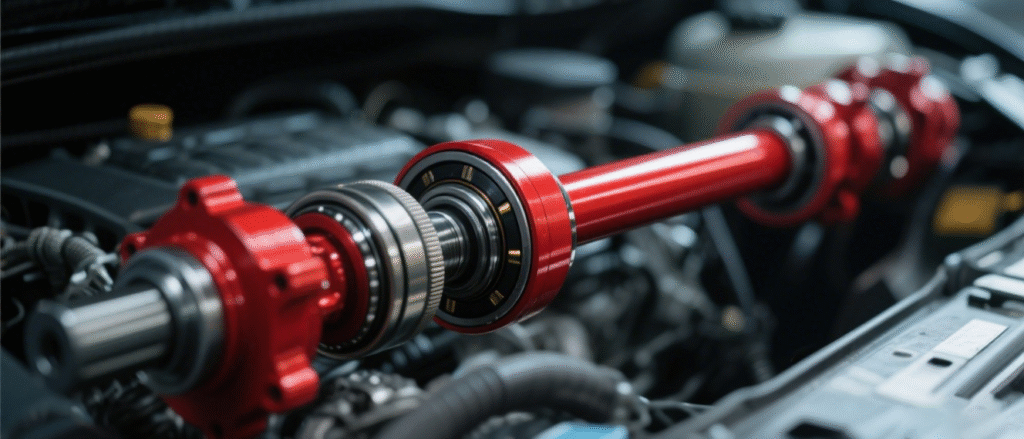

Qu'est-ce qu'un roulement de moyeu de génération 1 ?

A Génération 1 Roulement de moyeu est une unité de roulement intégrée conçue pour supporter la roue et permettre une rotation en douceur tout en supportant des charges radiales et axiales. Contrairement aux roulements à rouleaux coniques traditionnels qui nécessitent un réglage manuel, le roulement de moyeu G1 est pré-assemblé avec un jeu et une lubrification fixes.

Caractéristiques principales :

- Conception compacte et intégrée

- Jeu de roulement préréglé

- Pré-lubrifié avec une graisse de haute qualité

- Roulements à billes à contact oblique à deux rangées ou roulements à rouleaux coniques à deux rangées

- Grande durabilité dans diverses conditions de conduite

En raison de sa simplicité, le roulement de moyeu de génération 1 a été largement adopté dans les voitures particulières, les camionnettes et les véhicules commerciaux depuis des décennies.

Structure du roulement de moyeu de génération 1

Le roulement de moyeu G1 se compose généralement des éléments suivants :

- Anneau intérieur - Monté sur l'axe ou la broche.

- Anneau extérieur - Fixé au moyeu de la roue ou à l'articulation.

- Éléments roulants - Il s'agit généralement de billes ou de rouleaux qui réduisent la friction.

- Cage - Maintient un espacement correct entre les éléments roulants.

- Joints - Protège contre l'eau, la saleté et les contaminants.

- Graisse - Assure la lubrification pendant toute la durée de vie du produit.

La structure à deux rangées permet au roulement de supporter efficacement les charges combinées (radiales + axiales), ce qui est crucial pour les performances de la roue.

Fonctions d'un roulement de moyeu de génération 1

Les principales fonctions d'un roulement de moyeu de génération 1 sont les suivantes :

- Supporter le poids du véhicule

- Permettre une rotation fluide des roues

- Réduction de la friction entre les pièces mobiles

- Maintien de l'alignement et de la stabilité des roues

- Protection contre les contaminants externes

Sans un roulement de moyeu fonctionnant correctement, la conduite devient dangereuse en raison du vacillement des roues, du bruit et même du risque de détachement des roues.

Avantages des roulements de moyeu de génération 1

Bien qu'il existe des générations plus récentes (Gen 2 et Gen 3), le roulement de moyeu G1 offre toujours plusieurs avantages :

1. Le rapport coût-efficacité

Le coût de production des roulements G1 est relativement faible par rapport aux générations plus récentes, ce qui en fait un choix abordable pour de nombreux véhicules.

2. Fiabilité

Avec une étanchéité et une lubrification adéquates, ces roulements peuvent durer plus de 100 000 kilomètres dans des conditions normales.

3. Simplicité

Leur conception est simple, ce qui facilite leur fabrication et leur remplacement.

4. La polyvalence

Ils peuvent être appliqués à une large gamme de véhicules, des voitures compactes aux camions commerciaux.

Applications des roulements de moyeu de génération 1

Les roulements de moyeu de la génération 1 sont couramment utilisés dans :

- Voitures particulières

- SUV et camions légers

- Véhicules utilitaires

- Machines agricoles

- Équipements industriels

En raison de leur durabilité et de la simplicité de leur structure, ils restent populaires sur de nombreux marchés mondiaux, en particulier dans les régions où la sensibilité aux coûts est élevée.

Problèmes courants et conseils d'entretien

Comme tout composant automobile, les roulements de moyeu G1 sont sujets à l'usure.

Questions communes :

- Bruit (bourdonnement, grincement ou grognement) - Indique souvent que les éléments roulants sont usés.

- Vibrations des roues - Causé par un jeu excessif dans le roulement.

- Défaillance du capteur ABS - Dans certains cas, le joint du palier peut affecter les performances du capteur.

- Usure irrégulière des pneus - Résultat d'un mauvais alignement des roues dû à des problèmes de roulements.

Conseils d'entretien :

- Vérifier régulièrement s'il y a des bruits inhabituels pendant la conduite.

- Vérifiez le jeu de la roue en faisant basculer le pneu d'avant en arrière.

- Remplacer immédiatement le roulement si des signes d'usure apparaissent.

- Utilisez toujours des pièces de rechange de haute qualité pour garantir la sécurité.

Il convient de noter que les roulements de moyeu de la génération 1 sont unités non utilisables; lorsqu'ils sont défaillants, ils doivent être remplacés dans leur ensemble.

Comparaison : Roulements de moyeu de la génération 1, de la génération 2 et de la génération 3

Au fil du temps, la technologie automobile a progressé, ce qui a conduit au développement des roulements de moyeu de génération 2 et 3.

Génération 1 Roulement de moyeu:

- Unité simple et compacte

- Nécessite un raccord à sertir lors de l'installation

- Coût moins élevé

Génération 2 Roulement de moyeu:

- Bride intégrée pour une installation plus facile

- Rigidité et performances améliorées

- Plus adapté aux véhicules à traction avant

Génération 3 Roulement de moyeu :

- Comprend le moyeu et la bride de montage en un seul ensemble

- Simplifie davantage l'installation

- Souvent intégrés aux capteurs ABS

- Un coût plus élevé mais des performances supérieures

Alors que les roulements Gen 2 et Gen 3 dominent les véhicules récents, le roulement de moyeu G1 est encore largement utilisé dans de nombreux modèles en raison de son coût avantageux.

Guide d'achat : Comment choisir le bon roulement de moyeu de génération 1

Lors de l'achat d'un roulement de moyeu G1 de remplacement, tenez compte des facteurs suivants :

- Compatibilité OEM - Toujours respecter les spécifications de votre véhicule.

- Type de palier - Choisissez entre des roulements à billes ou des roulements à rouleaux coniques en fonction de la charge requise.

- Qualité des matériaux - Optez pour de l'acier à haute résistance et des joints durables.

- Réputation de la marque - Des fabricants de confiance garantissent de meilleures performances et une plus grande longévité.

- Couverture de la garantie - De bonnes conditions de garantie témoignent de la confiance dans le produit.

Perspectives d'avenir des roulements de moyeu

À mesure que les véhicules évoluent vers l'électrification et des performances accrues, la technologie des roulements de moyeu continue de progresser. Si les roulements de moyeu de génération 1 restent largement utilisés dans les applications sensibles au coût, le marché s'oriente progressivement vers les roulements de génération 2 et 3 en raison d'une installation plus facile, d'une meilleure intégration avec les systèmes électroniques et d'une plus grande durabilité.

Cependant, pour de nombreuses réparations après-vente, le roulement de moyeu G1 restera un choix essentiel et abordable pour les années à venir.

Conclusion

Les Génération 1 Roulement de moyeu est l'un des composants les plus importants pour la sécurité et la performance des véhicules. Grâce à sa structure compacte, sa rentabilité et sa fiabilité éprouvée, il continue de servir des millions de véhicules dans le monde entier. Bien que les nouvelles générations offrent des fonctionnalités avancées, le roulement de moyeu G1 reste une pierre angulaire de l'industrie automobile, en particulier sur les marchés qui privilégient l'accessibilité et la simplicité.

Que vous soyez propriétaire d'une voiture, mécanicien ou fournisseur automobile, comprendre les caractéristiques et l'entretien des roulements de moyeu de la génération 1 vous aidera à prendre des décisions éclairées et à assurer une performance optimale de votre véhicule.